- New

1. [Fuel Supply System & Intake System Cleaning]: C200 Improve fuel supply, full combustion, and reduce exhaust emissions; Reduce carbon deposits, increase the oil-gas mixture ratio, and smooth idle speed.

2. [TWC Converter On-vehicle Cleaning ]: AUTOOL Fuel Injector Cleaner is able tp solve the problems of weak acceleration and difficulty in increasing engine rpm and vehicle speed, bring you the best using experience.

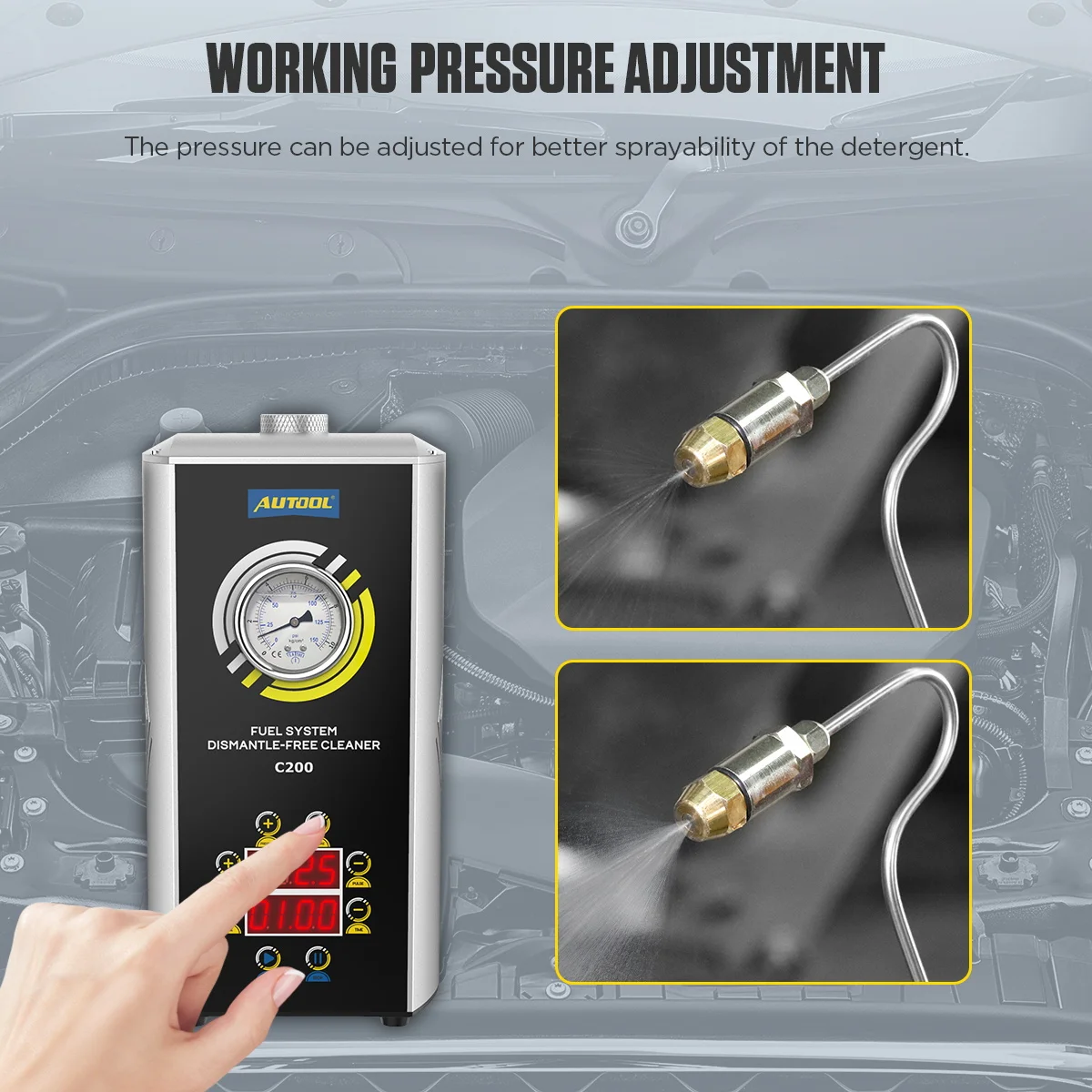

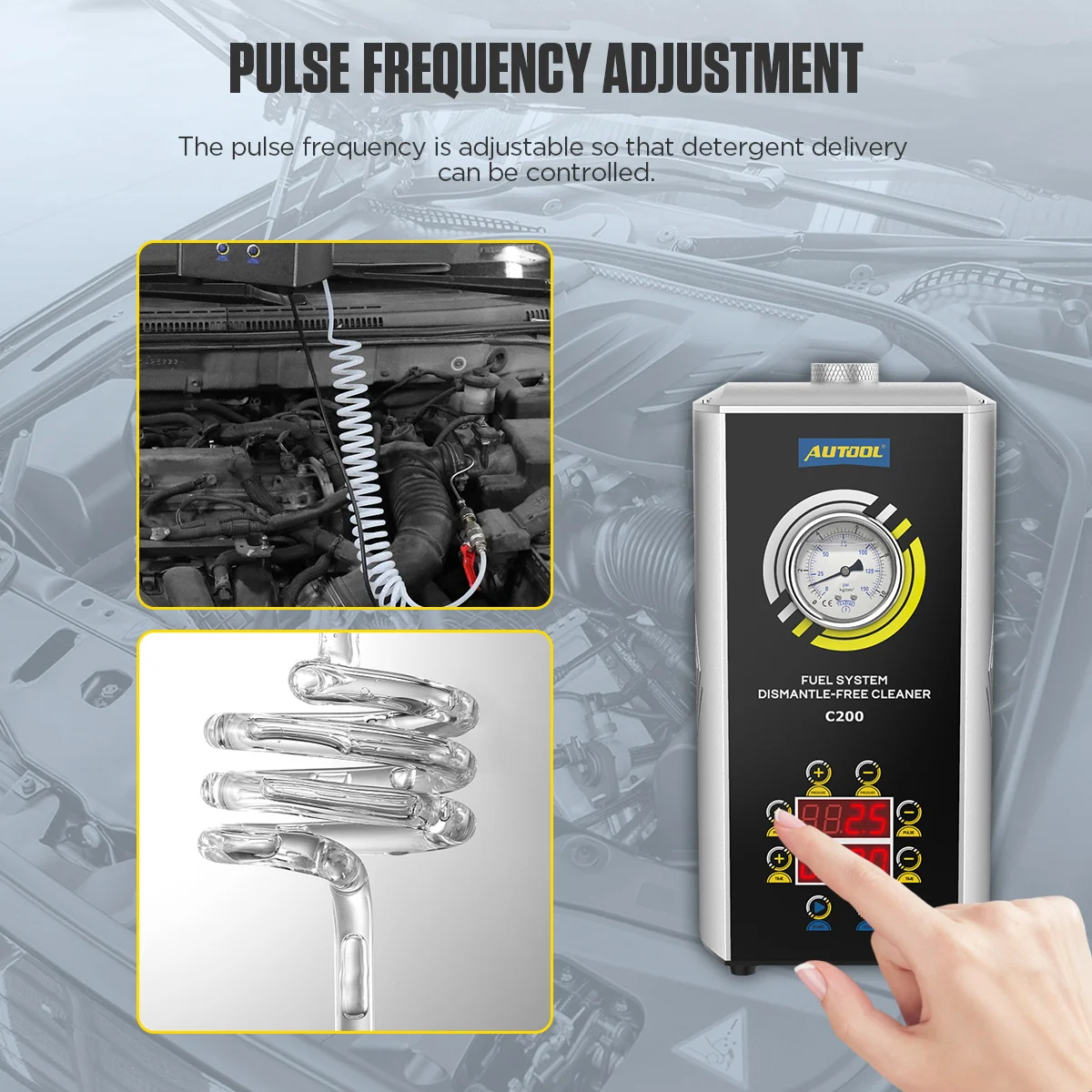

3. [Pulse Frequency & Working Pressure Adjustment]: The pressure can be adjusted for better sprayability of the detergent; The equipment can be cleaned automatically within a set working time.

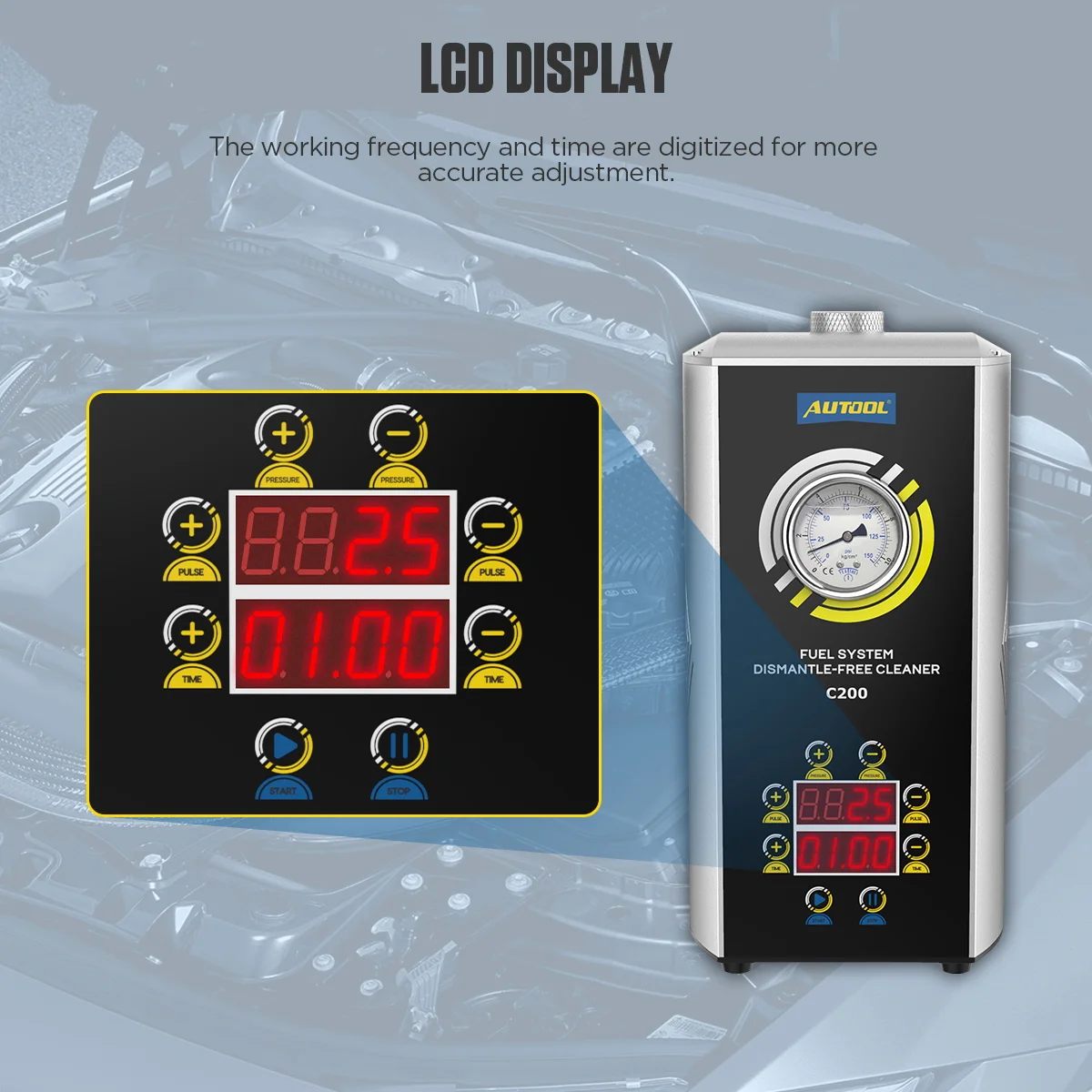

4. [LCD Display]: The working frequency and time are digitized for more accurate adjustment.

Security policy(edit with the Customer Reassurance module)

Security policy(edit with the Customer Reassurance module) Delivery policy(edit with the Customer Reassurance module)

Delivery policy(edit with the Customer Reassurance module) Fast Delivery(edit with the Customer Reassurance module)

Fast Delivery(edit with the Customer Reassurance module)AUTOOL C200 Auto-Injector Cleaner

C200

AUTOOL C200 Fuel Injector Cleaner Dismantle Free Fuel Injector System Flushing Machine

AUTOOL C200 is a newly designed smart on-vehicle injector cleaning machine, which can effectively remove the carbon deposits from the engine fuel system, combustion chamber, and intake and exhaust components. At the same time, it is able to clean the throttle, intake manifold, and turbocharged engine three-way catalytic to save fuel, reduce harmful exhaust emissions, and restore engine performance as new.

AUTOOL C200 Auto Fuel Injector Cleaning Machine Features

1. [Fuel Supply System & Intake System Cleaning]: Improve fuel supply, full combustion, and reduce exhaust emissions; Reduce carbon deposits, increase the oil-gas mixture ratio, and smooth idle speed.

2. [TWC Converter On-vehicle Cleaning ]: AUTOOL C200 Fuel Injector Cleaner is able tp solve the problems of weak acceleration and difficulty in increasing engine rpm and vehicle speed, bring you the best using experience.

3. [Pulse Frequency & Working Pressure Adjustment]: The pressure can be adjusted for better sprayability of the detergent; The equipment can be cleaned automatically within a set working time.

4. [LCD Display]: The working frequency and time are digitized for more accurate adjustment.

C200

C200

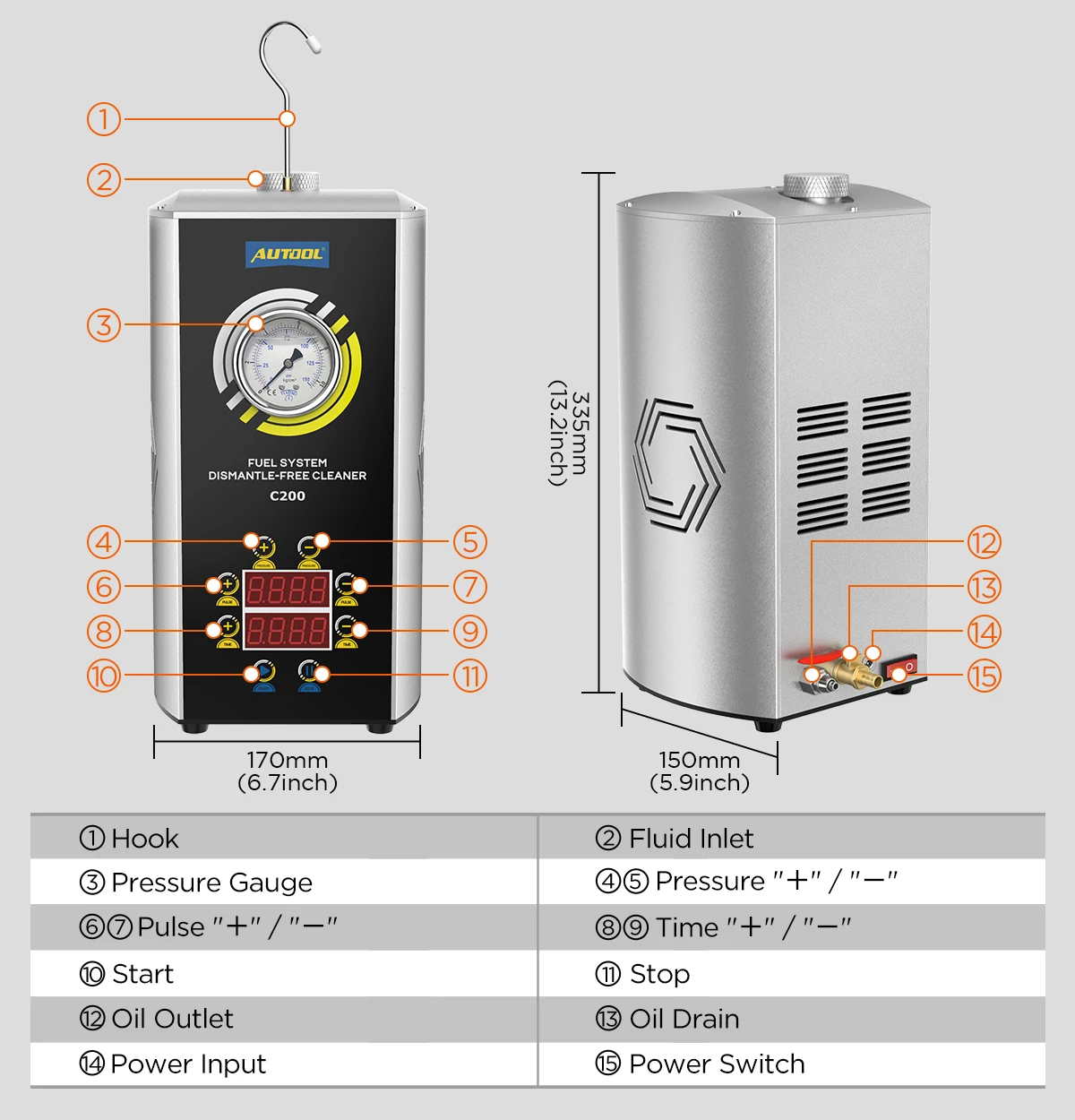

Schematic Diagram (Auto-Injector):

①Hook ②Fluid inlet

③Pressure gauge ④PRESSURE“+”

⑤PRESSURE“-” ⑥PULSE“+”

⑦PULSE“-” ⑧TIME“+”

⑨TIME“-” ⑩START

⑪STOP ⑫Oil outlet

⑬Oil drain ⑭Power input ⑮Power switch

Operation Instruction:

1、Fill the ultrasonic detergent to the tank, hook the equipment on the hood, and connect the positive and negative electrode of the battery with the clamps.

2、Three-way Catalytic Intake Valve On-vehicle Cleaning

⑴ Connect the output pipe of the equipment with the vacuum negative pressure pipe of the engine, then press the power switch and start the engine, running at idle speed, and start cleaning.

⑵ Press the START button, and adjust the pulse frequency by pressing the PULSE”+” or “-“. Then adjust the liquid output pressure through the PRESSURE”+” or “-” button. The greater the pressure value, the faster the liquid will be discharged. The normal pressure is 2.5-3kg.

⑶ Set the cleaning time: adjust by the “+” and “-” button, generally about 10-15 minutes.

3、Throttle On-vehicle Cleaning:

⑴ Connect the equipment cleaning nozzle, and spray detergent to the intake pipe. Start the engine, running at idling speed, and cleaning begins.

⑵ Press the START button, and adjust the pulse frequency by pressing the PULSE”+” or “-“. Then adjust the liquid output pressure through the PRESSURE”+” or “-” button. The greater the pressure value, the faster the liquid will be discharged. The normal pressure is 2.5-3kg.

⑶ Set the cleaning time: adjust by the “+” and “-” button, generally about 10-15 minutes.

4、Fuel Injector On-vehicle Cleaning

⑴ First, block the vehicle oil inlet pipe, and connect the outlet pipe with the quick connector of the fuel injector fuel rail. Start the engine, running at idling speed, and cleaning begins.

⑵ Press the START button, and adjust the pulse frequency by pressing the PULSE”+” or “-“. Then adjust the liquid output pressure through the PRESSURE”+” or “-” button. The greater the pressure value, the faster the liquid will be discharged. The normal pressure is 2.5-3kg.

⑶ Set the cleaning time: adjust by the “+” and “-” button, generally about 10-15 minutes.

5、After the countdown of the equipment is finished, hold idling speed for a few minutes before turning off the engine.

6、Restore the vacuum pipe, start the engine again, and slowly step on the accelerator to drain the waste liquid.

Package includes:

1pcs * Main Unit;

1pc* Power cable

1pc* Oil pipeline

1pc* TWC joint

1pc*Inlet system joint

1pc*Hook

1pc* Fuel system joint

1pc* hoops

1pc* PU waterproof bag

1pc* User manual

No customer reviews for the moment.